Building a Canoe, Phase 1

Been paddling since I was a boy. Owned quite a few paddle craft, both canoes and kayaks. Have three right now- all rotomolded. Never wanted boats with wood- too much maintenance. Even read McPhee’s Survival of the Birch Bark Canoe. Loved the book, but it didn’t change my attitude.

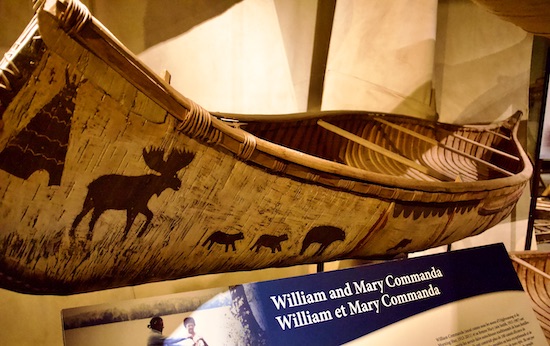

Then, during the summer of 2022, I visited the Canadian Canoe Museum in Peterborough, Ontario. Hundreds of hand-crafted vessels, way past beautiful. Powerfully organic. You could feel the ghosts of the boat builders in that building. As if I’d been struck by lightning, I now wanted to build a canoe.

After I got home, research ensued. Trips to the library, to bookstores, time on the web. Saw many different designs, all attractive. Then I came across the Cape Falcon Kayak website, watched the videos. Correspondence with Brian followed. In October I bought the plans for the 66 canoe.

Mind you, I’m not a woodworker, and don’t have a planer, or a table saw, or any expertise. I had to find a friend with the equipment who would give me instruction and let me use the stuff. The plan was, I’d trade him drum lessons for tool lessons. I still had quite a few hand tools and all the materials to buy. And I had a paddle trip and Christmas coming up.

Tool purchasing started. I built some sawhorses, and capture forms, and a steam box. New year’s passed, and I started looking for the wood I’d need.

I thought finding the wood would be easy. HA! I’m in Florida. White oak doesn’t grow here. Neither does western cedar. After calling or visiting every wood dealer in central Florida, I found a source for western cedar, the Ole General Store in Geneva. Only $140 a board (1x6x14), plus shipping. Times two. Ouch. And one of those expensive boards had four knots.

As it turned out, with the knots and the loss of material from sawing, I needed another board. Rather than go through the time and expense of ordering another western cedar board, I bought a piece of local cypress from the Ole General Store, 14 feet long, four-quarter, four inches wide, $45. I’ll use one piece in each gunwale, a piece for the keel, and my rub rails. It will make the finished boat a pound or two heavier. I can live with that.

I used Brian’s recommendation for the best place to get the oak, Swan’s in Wisconsin. He had what I needed, still in a log. But everything is frozen in January in Wisconsin, so I had to wait until a thaw before he could cut it.

The plot thickened. My friend with the tools got long COVID. I thought I’d practice my power tool skills on pieces of pine I had. No, you won’t. No practice for you!

Finally, in early March, the bending wood came. My poor friend is still sick. Somewhat frustrated, I looked for another option.

Another friend, Mike, who has a saw and a planer (both portable), used to be a finish carpenter and a commercial building contractor. He visited me- we got all the cutting and planing done in one day. I have finally started my build!

Brian Schultz at Cape Falcon Kayak recommends using Gorilla Glue to laminate the gunwales together. In my naivete, I bought Gorilla Wood Glue while purchasing supplies, way back last year. Not the same stuff. I watched the lamination video again before starting my laminating, and realized that, unlike Tom Wolff, I had The Wrong Stuff. Another trip to the hardware store ensued. And hey! Buy a couple more clamps while you’re at it!

I’ve already admitted to not being a woodworker. Many of the tools needed for this project were off my radar. One of them was a device called a “plunge router.” Brian showed what it was in his video. Now I have to buy one. No used ones on Craigslist. I read lots of reviews, and went with the Chicago Electric. Yes, I know it’s probably a POS. I’m not buying a $500 router to build a single canoe, sor-ree. Hopefully it will make the 50 holes I need.

Another device was a wallpaper steamer. This was actually hard to find, and I’m not talking Craigslist here. Neither Ace Hardware nor Home Depot had one unless purchased online. No, I don’t want it next week. I’m an American, of course I want it now. The local Lowe’s had one, I picked it up yesterday. The ribs are already cut. I want to get them bent and into the boat as quickly as possible.

Armed with a flat board, a zillion clamps of various configurations, three blocks, 24 ounces of the real Gorilla Glue, and the very important surgical gloves, I watched Brian’s video one more time, then commenced to gunwale glueing. The process went as close to Brian’s video as a goober who’d never done this could do. The spring clamps were hard to put on- these 70-year-old hands kept needed rests, kept cramping up. Aging is an adventure unlike any other.

I probably used too much glue, ’cause a lot of chisel scraping was needed afterwards to remove the excess. I left the clamps on overnight.

While the glue cured, I sanded my stringers, something I’d started the day before. Brian recommends rounding the stringers with a tool called a “Slickplane.” I almost bought one. Then I figured I would just sand them down. I already owned a sander.

This project started with 100 grit sandpaper. The first stringer took about 40 minutes. The switch was then quickly made to 60 grit sandpaper. The remaining stringers took 15-20 minutes each. If I intended to build more canoes, I would certainly buy the Slickplane. As it is, the stringers are sanded, with round edges, and that task is completed.

Friday, I visited my friend Mike Conneen, the table saw guy, to cut my gunwales. He does such amazing work- I’m lucky to have a friend like him. The gunwales came out beautifully. I picked up the router and the steamer on the way home. With any luck I’ll have a mostly framed canoe by Tuesday morning.

I’m building a canoe!

Every day is a blessing. Don’t waste it- Go fishing! Go paddling! Take a walk! Stay active!

John Kumiski

www.johnkumiski.com

www.spottedtail.com

www.spottedtail.com/blog

All content in this blog, including writing and photos, copyright John Kumiski 2023. All rights are reserved.

Recent Comments